[XCAR Technology Original]

As the most practical solution to solve the environmental problems of vehicles, hybrid technology is definitely one of the hot technologies pursued by major manufacturers. As the "overlord" of this technology, after more than 40 years of research and development, Toyota’s THS series-parallel hybrid technology has been recognized as the most mature and effective solution, and has achieved great success in the Japanese and American markets. As a technology-based Honda, it seems that it has not been as beautiful as Toyota in the field of hybrid power, but this does not mean that Honda is behind in technology.

Let’s take a look at Honda’s divine logic in hybrid technology through its development in hybrid technology and the latest hybrid system.

Brief history of Honda hybrid technology;IMAthe story of

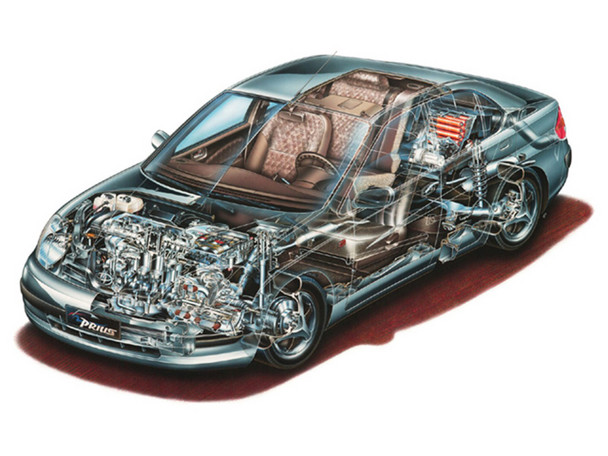

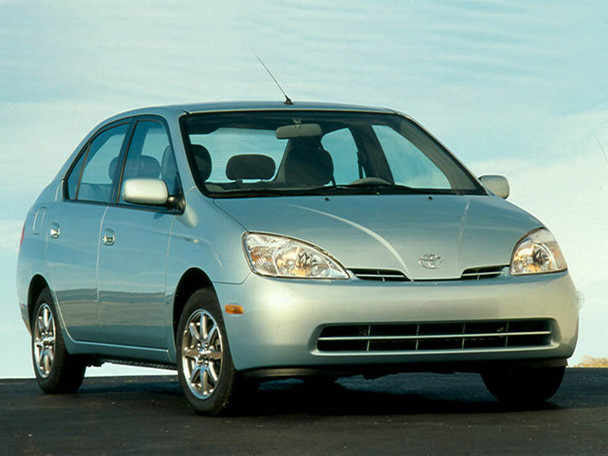

In 1997, the Prius, as the originator of hybrid vehicles, was officially put on sale in the Japanese market. In the same year, Honda also exhibited a hybrid vehicle — — First generation Insight.

This hybrid car seems to be more different and extreme than the first-generation Prius. The drop-shaped body, hidden rear wheels and sharply narrowed rear end all meet the criteria of aerodynamic optimization design of the car body. In the end, its wind resistance coefficient is only 0.25, which is still beyond the reach of few people.

Not only that, the first-generation Insight and Honda’s legendary sports car NSX were produced in Tochigi factory, and the all-aluminum body structure was also used to reduce the body weight, so that its body weight was only 838kg (manual transmission version).

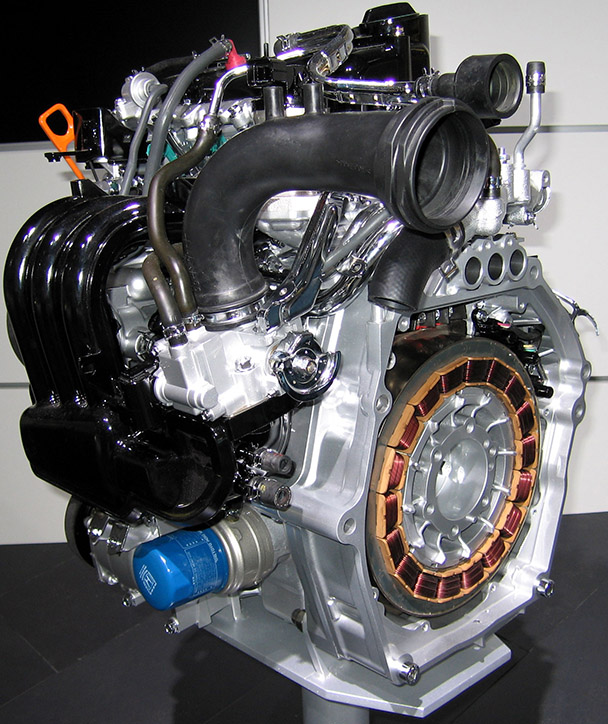

The biggest highlight of Insight is the hybrid device that Honda calls Integrated Motor Assistant System (IMA). As its name suggests, this system integrates a 10kW motor on the crankshaft of the three-cylinder engine with a displacement of 1.0L. The main task of this motor is to assist the engine to drive the vehicle and start the engine, but it cannot drive the vehicle forward independently. In addition, it also plays the role of a generator: when the vehicle slows down and brakes, it can convert excess energy into electric energy and store it in the Ni-MH battery behind the seat. The prototype of parallel hybrid power created by this system has been followed by many manufacturers in the future.

With all efforts, the first-generation Insight achieved extraordinary fuel economy: the comprehensive fuel efficiency certified by EPA in the United States reached 53mpg (equivalent to fuel consumption of 4.4L/100km), and its expressway fuel efficiency reached an incredible 61mpg (equivalent to fuel consumption of 3.9L/100km). You know, the EPA fuel efficiency of the first-generation Prius was 42mpg(5.6L/100km). This achievement has made it still ranked first in the EPA’s most fuel-efficient model.

By the way, the first generation of Insight was the first hybrid car listed in the United States (December 1999), and the Prius was seven months behind it.

Of course, being able to achieve such achievements also requires a price — — In order to pursue low fuel consumption, Honda’s engineers have "pushed too hard": the aggressive body can only accommodate two passengers, and the small engine is doomed to bring no driving pleasure.

Since then, Honda has launched a series of hybrid vehicles based on IMA hybrid system, including Civic, Accord (first generation hybrid) and hybrid sports car CR-Z, and Insight also launched the second generation vehicle in 2009. Compared with the first generation, this generation of models is obviously not so radical, the body style has become a more practical five-door hatchback, and the power system has also been upgraded. The consequence is that the new fuel economy is not as good as the previous generation, and it is not like the rival Prius of the times. Honda’s hybrid models have also been recognized in the market because of their excellent cost performance and good performance.

Comparing Honda’s IMA hybrid system with Toyota’s THS hybrid system, we can see that the two manufacturers initially adopted different design concepts: Honda’s design makes the whole system as simple as possible, exerts the maximum efficiency of the electric system in the smallest possible volume, and cooperates with the lightweight and low wind resistance design to improve the fuel efficiency of the vehicle, so Honda’s IMA system is usually also called a moderate hybrid system; Toyota, on the other hand, focuses on using the range with the highest engine efficiency to improve the proportion of electric drive. Therefore, it does not hesitate to use two sets of complex planetary gears to split the power of the engine, thus creating a set of complex hybrid drive methods. Therefore, Toyota’s THS system is called a heavy hybrid power system.

These two technologies have their own advantages and disadvantages: Honda’s IMA system has the advantages of simple structure, small size and low cost, but the power system has limited capacity and cannot maximize the efficiency of the engine; THS, on the other hand, thanks to the powerful and complex hybrid system, the engine can be separated from the wheels, so that it can run in the most efficient range as much as possible, but at the same time, the cost increase can not be ignored. But in terms of technological advancement, I have to say — — THS is better.